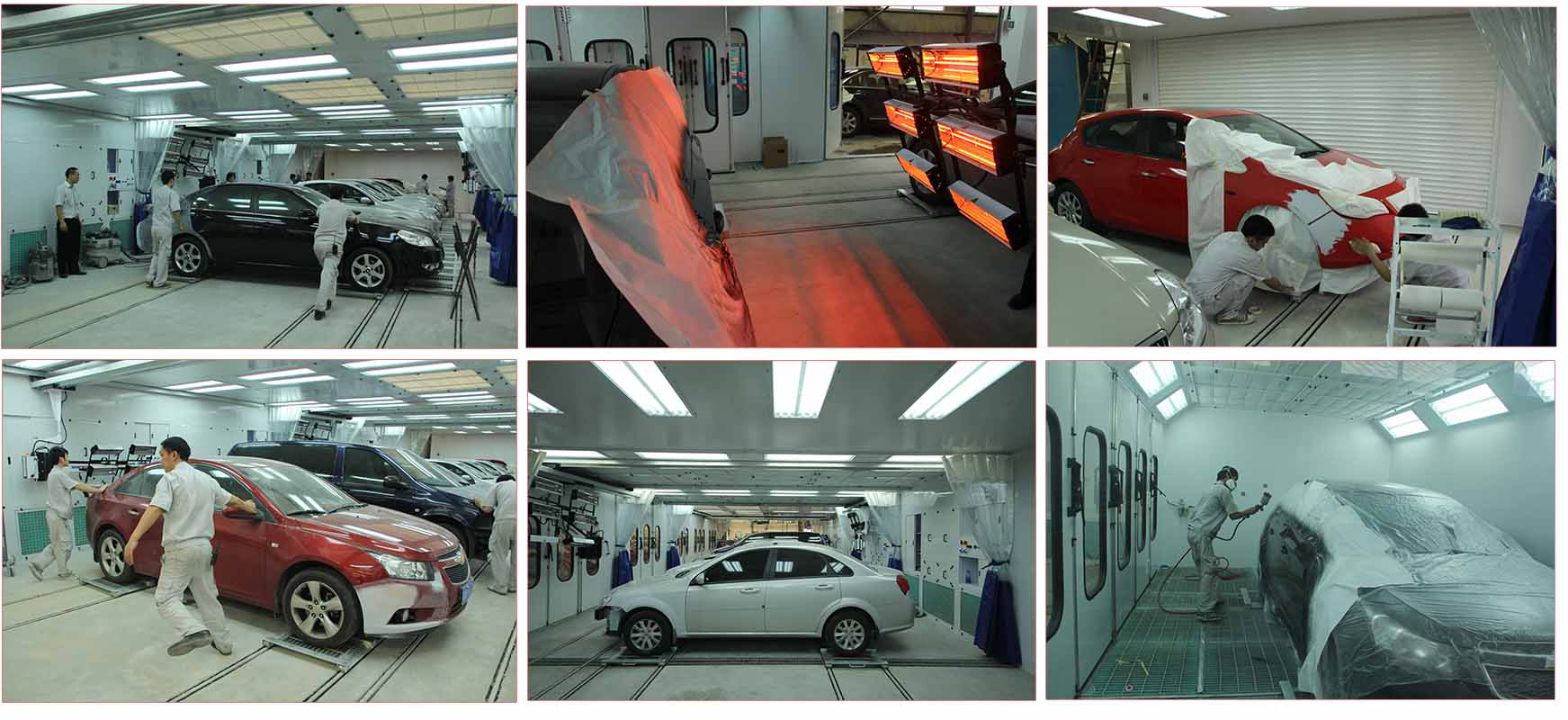

Spray Booth Production Line

The Spray Booth Production Line was designed regarding the vehicle model, production quantity, and also the site condition of the repairing shop. This design can promote production efficiency and save a lot of running costs for the 4S workshop.

Take an example of the Buick Spray Booth Production Line, composed of eleven working stations. Buick has one Reserved Working Station, four paint preparation bays, one prep station for a floating coat, one prep station for shielding, two spray booths, and two polish rooms.

Different paint finishing apps demand other solutions. By constantly improving material design and technology, manufacturers assure the quality supply of Prep Station and Spray Booth Working Station based on project needs.

For high-end prep station and spray booth working stations, experienced staff must be appointed having complete knowledge of the latest technology models and international quality standards. Manufacturers give custom solutions to fulfil the demand of the biggest automobile paint finishing apps so that the most efficient prep stations can be availed of quickly.

Do You Have A New Project In Your Mind?

Can We Offer Any Help?

More Projects…

Open Face Cross Draft Paint Booth

YOKISTAR produced and sold this Open Face Cross Draft Paint Booth with a dry filter […]

Water-based Paint Spray Booth

YOKISTAR offers a high-quality water-based paint spray booth that will allow you to paint automobiles quickly […]

Industrial Spray Booth with Heat Recuperator

Yokistar is an industry-leading company that specializes in customized industrial spray booth systems, ranging […]

Train Spray Booth

Yokistar has an outstanding track record of successful Train Spray Booth delivery to its customers, and with […]